In 1990, Mike Miller combined his experience in exotic alloy manufacturing with his love for automobile racing and formed Stealth Technologies. With just five employees, Miller quickly established Stealth as a key supplier of high-performance auto parts to some of the top racing teams and engine parts distributors in the U.S. At the same time, groundwork was being laid to enter the business of supplying complex net-shape forgings to the orthopaedic implant industry. Miller was instrumental in introducing these near-net forgings to the medical industry.

During this initial period, Miller was invited by one of the major orthopaedic implant supply companies to serve on a planning committee. The committee was formed to explore the possibility of using near-net shape forging technology to replace the gross forging technology that was currently being used in manufacturing orthopaedic implants.

Almost immediately Stealth became a major supplier in the implant forging business, with medical revenues that were quickly surpassing automotive. The intervening years have been marked by several noteworthy events. In 2001, Stealth acquired Hy-Vac Medical Technologies in Collierville, Tennessee, a company that specializes in porous coating of implants. In 2003, the Biomaterials Division of Astro-Met was purchased to merge with Stealth’s coating division and place the company as a leader in orthopaedic porous coating.

Orchid Orthopedic Solutions, LLC was formed in 2005 when Churchill Equity Partners acquired majority ownership of Stealth Medical Technologies, Unique Instruments, Unique Design, Bio Coat and Bio Vac. In 2005, Mike Miller was named Chief Executive Officer of Orchid.

MACDEE was the next acquisition in 2006, adding precision machined and molded plastics to Orchid’s array of capabilities. In 2007, Orchid merged with another fund of companies that Churchill owned. These included Micro Precision Swiss, Keller Engineering and Anzon. Orchid Orthopedic Solutions now employs more than 1,000 people at its various locations, and Mr. Miller continues as the CEO today.

BONEZONE: Tell us about Orchid.

Mike Miller: Orchid is a full solution provider focused on the orthopaedic market. We help companies bring their products to market by utilizing our vast and varied capabilities in both design and manufacturing. This is done through our management of the entire value stream of the product or, if the customer prefers, using our services à la carte to enhance their own internal manufacturing and design.

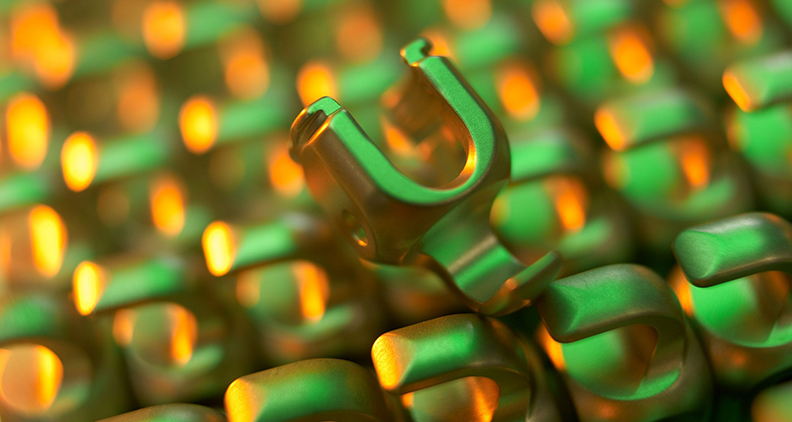

Our specific manufacturing capabilities include forging, turning, milling, grinding, EDM, color coding, laser marking, TiN coating, diamond coating, passivation, gun drilling, injection molding, laser cutting and welding, assembly, sterile and non-sterile packaging, titanium plasma spray coating, hydroxyl apatite coating, sintered bead coating, specialty coatings and resorbable blast media surface treatments.

Our design services include computer aided engineering, prototyping, pre-clinical testing, quality and regulatory consulting, broad concept development, thorough feasibility confirmation, innovative design services, qualification testing and validation protocol writing.

Markets we participate in are joint reconstruction, trauma, spine, dental, extremities, biologics and sports medicine.

Mike Miller: This is a tumultuous time for all of us in the orthopaedic industry. There are challenges from changes in the healthcare industry, the medical device tax and increased scrutiny from regulatory agencies. On top of this, our customers are moving towards a focused supply base, which means they are consolidating their vendors with companies they want to partner with for future growth. Orchid’s biggest challenge is finding ways to provide more and more value for our customers as we navigate through the changes in the market.

BONEZONE: How is Orchid addressing this challenge?

Mike Miller: We have invested heavily in areas where we can have the biggest impact on customer value. Our lean acceleration program is focused on reducing overall costs in our value streams. Orchid began its lean journey five years ago. Altor, our new owners, recognized the value and importance of utilizing lean as a way of doing business. During their due diligence when evaluating our company, they saw the evidence and successes we had achieved working with our customers to remove wastes out of the value stream. They want to accelerate these improvements that we and our customers have experienced by providing the necessary direction and resources. Also, training employees in problem solving and targeting the removal of the soft costs that are related to the process flow, such as excess shipping, material movement through the shop and reduction in inventory, are areas we are investing in.

Another important aspect we are addressing is that Orchid continues to bring customer value through the addition of niche, complementary businesses. Most recently, we have signed an agreement to acquire Sandvik Medical Solutions (SMS). We are excited to be able to provide more capabilities to our customer base and look forward to the challenge of merging Orchid and SMS together. Orchid and SMS complement each other well, and I see only exceptional opportunities with this combination – more than the sum of their parts. Our customers will benefit greatly from this fit, and we look forward to increasing customer value through our collaboration and implementation of best practices.

Finally, we apply our customer centric culture in the partnerships we form. There are opportunities for us to work with our customers to remove waste, not only in our companies, but also between them. We have begun collaborating together to streamline the entire product value stream from raw material through finished, packaged product to create a lean enterprise. It is a very exciting time for our company.

BONEZONE: So why is lean so exciting for Orchid?

Mike Miller: Who isn’t excited about removing wastes? We get to reduce costs, shorten our lead-times, empower our workforce, increase value for our customer and create something much greater than ourselves. Some other “symptoms” of a good lean program are a better focus on quality, total lower landed costs and simplified logistics. We are very excited about working with our customers on these types of activities. It’s rewarding for all of us.

BONEZONE: Give me an example of how you have applied lean and brought value to a customer?

Mike Miller: One good example is how we established a Kanban pull system between our company and our customer. Our value stream is tied in with our customer’s, allowing them to pull product forward when we receive a signal. We then replenish the stock. By utilizing this program, we reduced excess inventory, minimized wastes from overproduction and cut the lead time from weeks to a couple of days. It also allows us to streamline our production and plan it around what is efficient for us to keep our costs down. Keeping our costs down is what is valuable to our customers.

BONEZONE: How do you define customer value?

Mike Miller: We find out what the customer wants, what they find valuable and then we make sure to provide it. Our success will be found when we satisfy the customer’s needs and then provide more and more value through waste reduction.

We recognize the need in the industry for a supplier with market-separating customer service in areas such as quality, lead time and lowest total cost. We feel it is our responsibility to help our customers add profits and keep Orchid’s financial stability so that we are there for them long term. Using lean to stabilize the value stream, we minimize risk and allow for a predictable process. If we do these things, we will bring value to our customers.

BONEZONE: What advice do you offer to medical device companies on how to address the challenges in the market?

Mike Miller: Learn how to problem solve. Every employee must know how to solve problems and be empowered to contribute. Listen to what your customers are saying and do it. We have to keep getting better and better, or we will be left behind. That’s not going to happen to us. We are committed to success by providing others an opportunity to live a better life, whether it is the patients, our customers, the doctors, our employees or our communities, and by creating more value for them.

BONEZONE: Where do you see the industry going, five years from now?

Mike Miller: We see steady growth for the companies that have the courage to change and adapt to the market challenges.

The next five years will see a lot of changes in our industry. Regulation will always be a challenge, as well as price erosion. Companies that get better will be successful. Companies that don’t will cease to exist. I believe that orthopaedics is still the greatest industry to be in, and we are pleased to play a small part in its success.