Sponsored Content

Success with outsourcing additive manufacturing (AM) in orthopedics requires that OEMs partner with contract manufacturers that possess steep knowledge in AM. Medical device contract manufacturer rms Company watched AM develop and evolve, and ultimately saw an opportunity to offer more to its customers through AM implants, which provide functionalities that cannot be manufactured any other way.

rms chose to work with AM industry pioneer 3D Systems, and now provides a complete powder to package capability to medical device OEMs. Powder to package encompasses the entire manufacturing and post-processing workflow required to go from a digital file to a sterilized and packaged final product ready for the surgical suite. Over the course of four years, 3D Systems has helped rms expand its portfolio of direct metal printers from one machine to 30—backed by a process that ensures repeatability across machines and supply chains—enabling true scaled production.

rms was methodical in its selection of additive manufacturing technology and chose 3D Systems for its track record of success in healthcare applications. “3D Systems has proven to be a great partner—sharing lessons learned, guiding us in how to properly use the equipment, how to look at our total quality system, and beyond,” said Troy Olson, Director of Additive Manufacturing at rms.

More than Manufacturing

Beyond 3D Systems’ additive manufacturing solutions, which include hardware, software and materials, rms also took advantage of the decades of application expertise housed within 3D Systems’ Application Innovation Group to ensure that it had the best guidance possible. 3D Systems began adding value to the collaboration early by helping rms fill knowledge gaps to ensure rms’ successful integration of additive manufacturing within its broader portfolio.

“We don’t look at additive manufacturing as a standalone technology. We see it as a complementary technology to our existing capabilities,” Olson said. Specifically, consultation with 3D Systems’ healthcare team as well as 3D Systems’ technology transfer offering helped rms remove the guesswork from adopting additive manufacturing to streamline its transition to a new manufacturing process.

Together, the companies honed production processes while maintaining print quality. Technology transfer leverages pre-developed print files and processes, and includes professional account management, consulting, training across pre-qualified AM production processes, and installation. It also focuses on specialized tasks like how to run the machine, program the printer, set up files for printing, part supports and orientation, and part post-processing. Through transfer of process design, rms ensured its ability to print parts the way its customers want, without deviation.

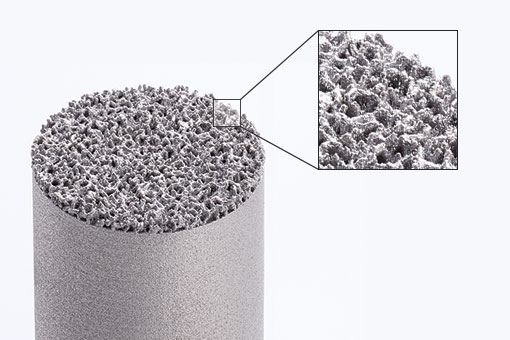

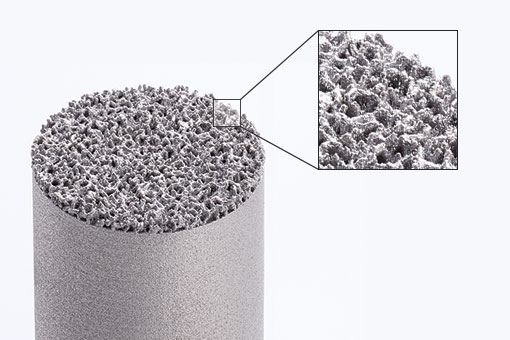

In addition to fostering AM expertise within rms, the collaboration provides them an ideal additive solution in terms of print quality and material properties, which is critical for the implants that rms produces for orthopedic OEMs. The best-in-class oxygen levels (<25 ppm) and inert printing atmosphere of 3D Systems’ direct metal printing (DMP) systems ensure exceptionally strong and accurate parts with high chemical purity, and the repeatability needed to produce implants for medical device OEMs. By using the same digital data package per part, 3D Systems machines enable scalability of production by delivering the same outcome across all DMP machines with no global off-sets.

“Our customer-focused approach and flexibility to partner with both medical device OEMs and contract manufacturers like rms helps OEMs accelerate their go-to-market strategies for launching new products,” said Gautam Gupta, Ph.D., Vice President and General Manager, Medical Devices for 3D Systems.

In-House Capability

Since adding its first AM machine, rms has grown its in-house expertise tremendously and has its own on-site laboratory for testing materials and printed test bars. rms handles all post-printing steps to ready products for final delivery, including heat treating, finishing, polishing, cleaning, packaging and sterilization management. The company says the future of AM is very bright, and it allows rms to deliver on its customers’ diverse needs. In fact, rms recently restructured its additive department as a stand-alone business unit within rms with dedicated resources in engineering, quality and operations leadership.

The early potential rms saw for AM technology is expanding beyond orthopedic implants for the spinal market. “We’re seeing more opportunities outside spinal implants,” said Lee Zachman, President of rms. “We’re in a very good position. We worked extremely hard to get where we are.” By partnering with 3D Systems, the effort has all been supported by decades of experience, enabling rms to streamline and accelerate its adoption of additive manufacturing while safeguarding its investment in a new technology and process to serve orthopedic OEMs.

3D Systems provides comprehensive products and services, including 3D printers, print materials, software and on-demand manufacturing services for the healthcare industry.