CAM Bioceramics, supplier of medical-grade ceramic materials, is supporting Admatec to enable the printing of medically approved ceramic material on Admaflex 3D printing systems, opening up opportunities for the medical and dental sectors.

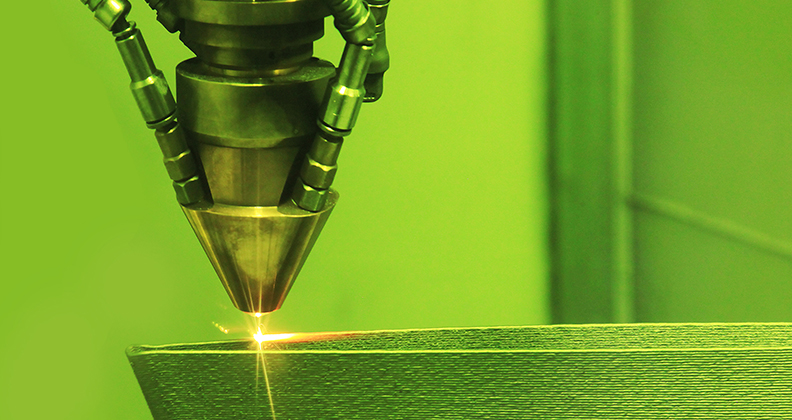

Tool-free Admaflex DLP 3D print technology can manufacture highly complex geometries, channels, lattice and honeycomb structures with features and wall thicknesses in the range of 100 µm. Admaflex 3D printing is an alternative to methods such as milling, allowing for efficient use of materials, or injection molding, which may be a slower process.

Admaflex DLP supports build volumes of up to 238 x 192 x 500 mm on one build platform. In case of small implants, many different geometries can be 3D printed simultaneously with the Multi-part printing software.

C. Hogeboom, CEO of CAM Bioceramics, said, “As a supplier for the Orthopaedic and Dental market, CAM Bioceramics acknowledges that 3D Printing will play an increasingly significant role in numerous patient treatment plans. Calcium Phosphate based bone reconstructions will play an important part in this next generation medical device solutions due to its proven biocompatibility. As one of the market leaders in this area, CAM Bioceramics actively partners with 3D print experts and promotes the evolution of 3D printed solutions.”