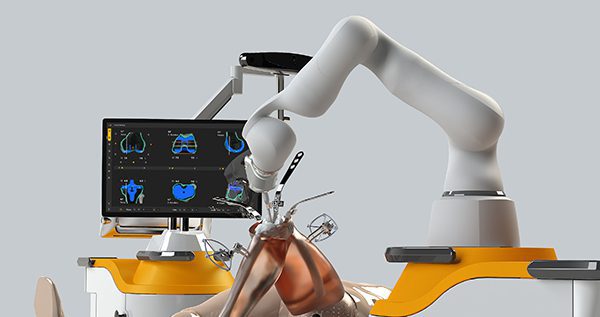

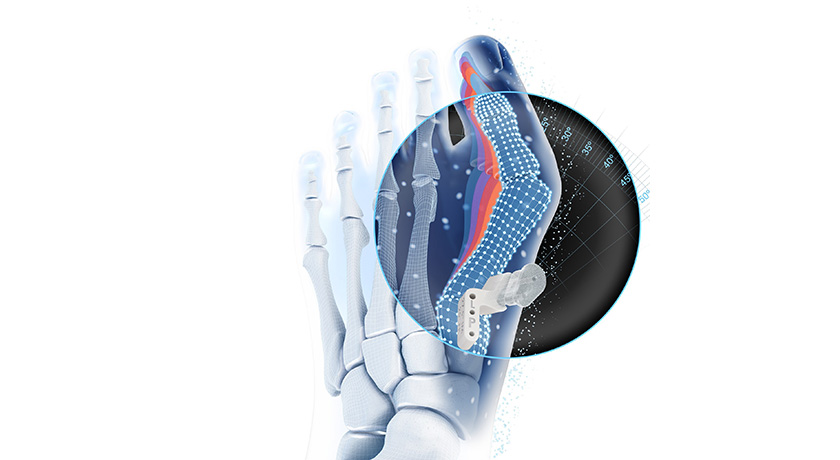

COVID-19 will present plenty of lessons for orthopedics. Joint replacement surgeon Vinod Dasa, M.D., says there will be a heightened focus on eliminating waste and reducing redundancies, especially in the “last mile” of the supply chain. One way to do that is to automate portions of the supply chain and operating room, allowing device companies better insight into procedure forecasting and inventory management.

We asked Dr. Dasa, Vice Chair of Academic Affairs in the Department of Orthopaedics at LSU and Chief Medical Officer of the logistics company SIGHT Medical, about the following:

- What’s been his experience since the postponement of elective procedures? What does he expect in the months to come?

- How will COVID-19 change the hospital/surgeon and device company relationship when it comes to supply chain logistics and operating room efficiencies?

- What components make up SIGHT Medical’s model? What has the data taught them?

CL

Carolyn LaWell is ORTHOWORLD's Chief Content Officer. She joined ORTHOWORLD in 2012 to oversee its editorial and industry education. She previously served in editor roles at B2B magazines and newspapers.