Renishaw launched InfiniAM™ Sonic acoustic process monitoring software to complement its InfiniAM suite of additive manufacturing (AM) monitoring tools. InfiniAM Sonic allows engineers to detect acoustic events within the build chamber and turn this data into useful information about build quality. The software is reportedly the first of its kind in the AM industry.

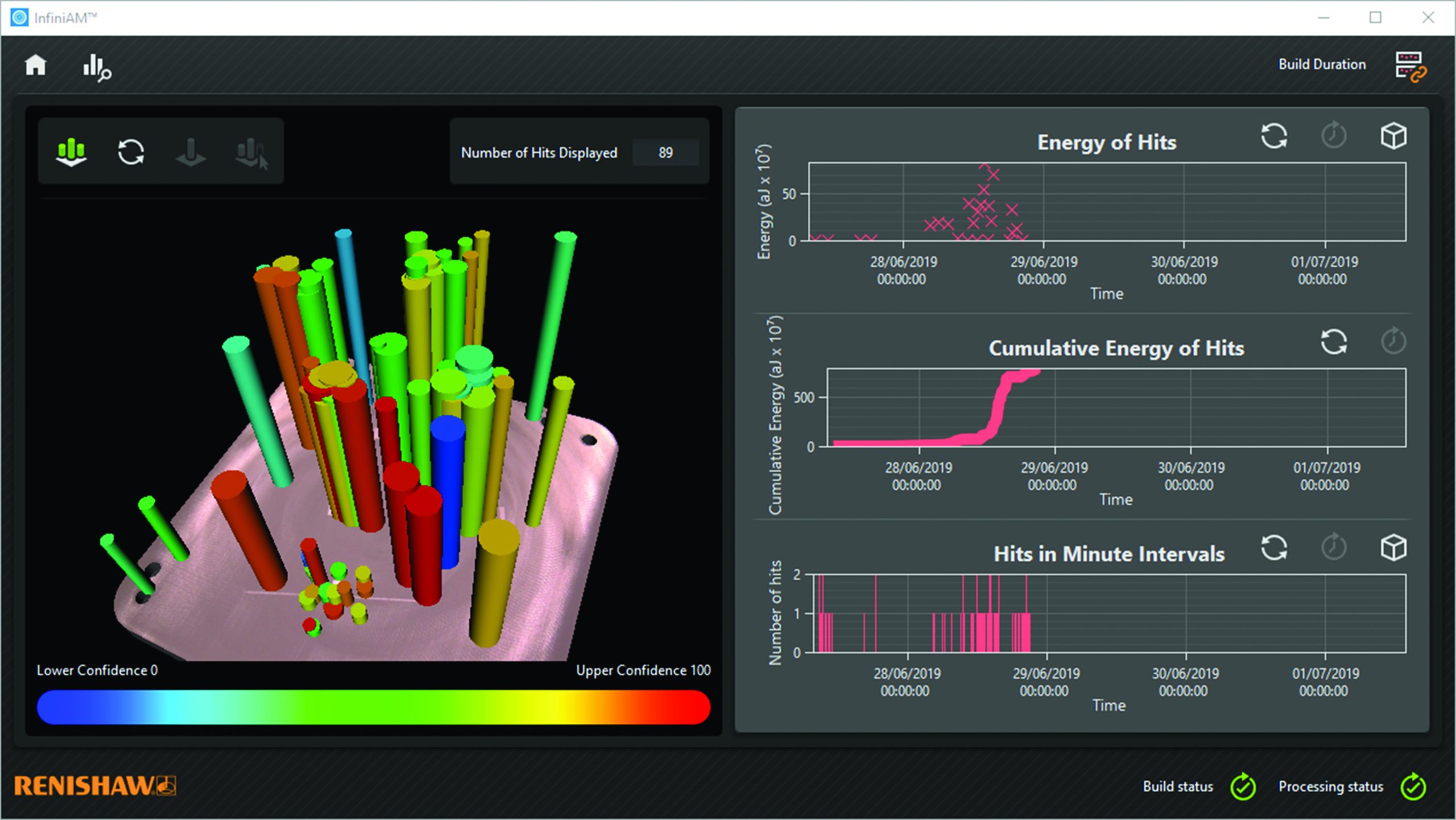

The package is installed into the RenAM 500Q system, and includes four acoustic energy sensors to detect minute vibrations and collect the sound waves so that they can be heard, viewed and analyzed. Four high-frequency sensors in different locations result in a slight time difference due to the speed of sound. The software triangulates the position of the noise on the build plate, and calculates its magnitude. This data can then be combined graphically with other sensor data to build a comprehensive view of the part and conditions at the time of build.

InfiniAM Sonic complements InfiniAM Central and InfiniAM Spectral, which lend an understanding of build quality, increased confidence in the build process and accelerated process development. InfiniAM Central is itself supported by a mobile app.

“The rapid heating and cooling that takes place during an AM build leads to residual stress in the part,” explained David Ewing, AM Product Manager at Renishaw. “While each laser weld results in a small amount of stress, residual stress can build up within the part, and if it increases past the strength of the metal, it may lead to a fracture in the support material or the part itself.”

“Renishaw’s InfiniAM software suite makes it a lot easier to understand what is happening during an AM build,” continued Ewing. “Spectral and Central give manufacturers ‘eyes’ inside their AM component and process – now we’ve launched InfiniAM Sonic as the ‘ears.’ These tools help engineers better understand their AM parts and processes, and identify potential causes of defects early in the process. This is particularly useful while developing and validating parts. The more data available, the quicker it is to confirm manufacturing is meeting specifications. Root cause investigation is simplified, and if necessary, the build can be stopped, saving material and time.”

Renishaw manufactures laser powder bed metal additive manufacturing machines. Its portfolio includes the RenAM 500Q that features four lasers in the most commonly used platform size.