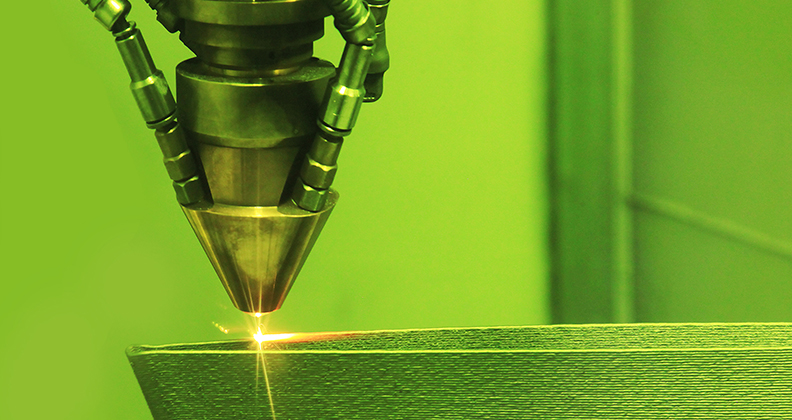

Renishaw is collaborating with Sandvik Additive Manufacturing to qualify new additive manufacturing (AM) materials, encompassing a broad range of metal powders like new alloy compositions that are optimized for laser powder-bed fusion.

Sandvik has one of the widest alloy programs for AM on the market, and has worked with Renishaw AM systems since 2018 at its Additive Manufacturing Division. Sandvik recently inaugurated a titanium atomizing plant and powder processing facility, and will now seek to qualify these alloys for medical and other applications.

“With our 157-year materials knowledge, our comprehensive range of in-house steels, duplex and super-duplex stainless steels, as well as nickel-based alloys and our new titanium powders, Sandvik now offers the widest range of AM materials to the market under the Osprey® brand,” said Mikael Schuisky, VP R&D and Operations at Sandvik Additive Manufacturing. “Renishaw’s open machines have enabled us to rapidly optimize process parameters for our alloys for use in many different applications.”

“Much of the innovation in AM in the next few years will come from the pairing of enhanced machine performance with improved alloys,” explained Stephen Crownshaw, AM Business Manager at Renishaw. “Better alloys mean better material properties, enabling AM components that are even more efficient and cost-effective. The consistency of Renishaw’s latest AM systems, combined with Sandvik’s material expertise, provides tremendous opportunities to advance AM processes and to make a stronger business case for AM.”

As well as qualifying materials for sale to other manufacturers, Sandvik Additive Manufacturing has developed a range of additive production applications.

“AM is transforming the manufacturing landscape, with better materials and equipment being the driving forces behind that change,” said Mikael Schuisky. “Sandvik’s unique end-to-end process knowledge – spanning raw materials, powder production, additive manufacturing and post-processing methods such as machining – puts us in the ideal position to help manufacturers and customers to exploit this exciting technology. Renishaw’s latest quad laser systems also help us to extract AM’s full potential.”