Numerous acquisitions have taken place in the orthopedic and spine industry recently, providing ripe timing for companies to implement additive manufacturing.

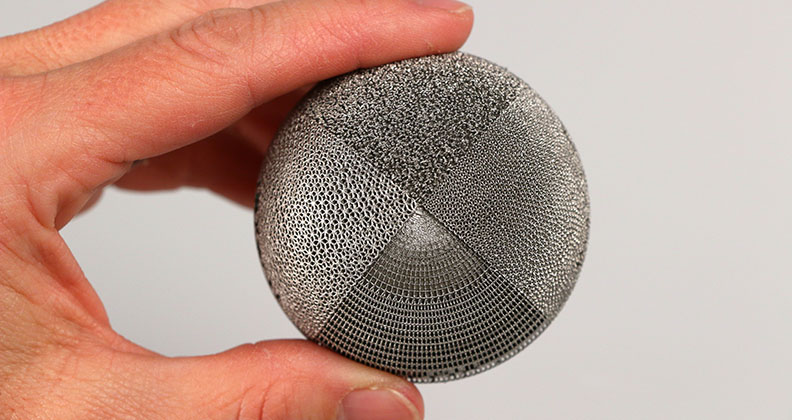

Large medical device manufacturers that want to leverage expertise and geographic reach to expand their footprint are purchasing small and medium-sized companies with innovative product portfolios. With the expansion of device manufacturers’ operations comes a need to increase supply chain capacity. This shift requires the traditional manufacturing workflow to scale to meet increased demand in the same amount of time, while continuing to deliver high-quality products for which these companies are renowned. This shift has also created an unprecedented opportunity to integrate additive manufacturing (AM) technologies into these traditional workflows to 3D print medical devices such as spinal cages and acetabular cups.

While orthopedic device manufacturers expand, new contract manufacturers enter the market to help address these capacity demands in an outsourced fashion. Manufacturers and service bureaus employ additive technology platforms that best meet their customers’ needs, resulting in a complex ecosystem of novice and experienced players using multiple technologies to make different kinds of implants and instruments. Variations in players and expertise necessitates guidelines for a harmonized validation approach so that we as an industry are able to create devices that meet the highest quality standards demanded by the healthcare industry. Robust process validations and build qualifications through witness coupons can result in elevated confidence that chemically and mechanically conforming parts are produced consistently.

A key component of improving the predictability of part quality is 3D printing software. There are several products available in beta versions that can create build simulations, predict the stress areas and provide guidance for optimal support structures for printing complex metal parts. As finite element analysis features are integrated and the software becomes more intuitive using artificial intelligence, engineers will be able to create optimal designs for critical components—and this will unleash unprecedented innovation in 3D printing.

As AM technologies expand their role in orthopedic device manufacturing, we will also see the technology become integral to the delivery of personalized medicine at point-of-care sites. This has already started to take shape at some of the elite hospitals in the world, where clinicians are able to create customized solutions for patient care by using technology available to them on campus. As the technology becomes more user friendly, a larger number of hospitals will be able to implement end-to-end solutions for personalized medicine, thereby changing the standard of care.

Overall, 3D printing has tremendous potential to shape the future of healthcare by unleashing innovation and disrupting existing models of manufacturing and patient care.

Gautam Gupta, Ph.D., Vice President of Business Development – Healthcare, 3D Systems