In 2012, surgeon brothers Alan BC Dang, M.D., and Alexis BC Dang, M.D., started working with 3D printing. In the short time since then, they’ve gone all-in on additive manufacturing, starting multiple programs at the University of California San Francisco (UCSF) and the university’s VA Medical Center, as well as serving as founding members and co-Chief Medical Officers of the new company, PrinterPrezz. In the course of a day, their 3D printing efforts touch patients, surgeons, students, device companies, contract manufacturers and service providers.

What entices them about 3D printing? “It makes our lives easier and our patients’ lives better,” Dr. Alan Dang said. “Innovative ideas can reach the market more quickly and technologies that enhance safety, performance, ergonomics and efficiency are all welcome.”

We came across Dr. Alan Dang, a spine surgeon, and Dr. Alexis Dang, a sports medicine surgeon, when PrinterPrezz came out of stealth in December 2018. The company was founded by the surgeons along with its Chief Executive Officer, who comes from the semiconductor industry, and Chief Operating Officer, who has a background in big tech, including Apple.

PrinterPrezz has an interesting open-ecosystem business model and collaborates across the supply chain with companies like GE Additive, Materialise, nTopology, Renishaw and SI-BONE out of its facility in Fremont, California.

How does the company’s structure work? What is the future of 3D printing in orthopedics? We asked Dr. Alan Dang for his perspective.

Tell us about your open-ecosystem. How does it work?

Dr. Dang: Additive manufacturing of medical devices in high volumes and with materials such as titanium alloy (Ti 6A-l4V ELI) is so complex that the majority of medical device companies, even many of the largest, rely on dedicated contract manufacturing facilities. For 3D printing, most manufacturing facilities are owned by or exclusively partnered with one brand of printers. If you go to facility A, you may only have the option of printing with equipment from manufacturer A. The problem is that no single printer is the best at everything. In the current closed ecosystem, a large medical device company may go to Contract Manufacturer A, be told that their design is not manufacturable due to complexity and cost, and ask for a re-design. The problem may not be with the medical device design, but with the printers that are available at that facility.

At PrinterPrezz, we have 3D printers from multiple vendors, which really makes the difference for our customers who are well established in the industry. We can tell our customers performance and cost metrics across different printing platforms so that they can choose the right option for them. This translates into shorter times to market.

In fact, the actual machine that the implant is printed on is just one of more than 50 steps to take a concept to market. At each of these steps, a number of different software and hardware tools are available. Our open ecosystem means that we can provide multiple alternatives for every step of the process.

The other element of the open ecosystem is that we don’t require customers to use PrinterPrezz for the entire path of concept to market. A small medical device startup may use all of our resources, including contracted design work with weekly meetings with us involved all the way to coordinating a FDA 510(k) filing. A well-established industry player may only use us as a technical consultant or as a pure contract manufacturing service.

This open-ecosystem is unusual in medical device design and manufacturing, but we’ll be the first to admit that we didn’t come up with the idea ourselves. The semiconductor industry has operated this way for decades, with the largest chip fabs having multi-vendor support for the various tools required in the many steps of making a chip. The same factory may produce different chips utilizing various combinations of tools and process chips destined for Apple, Samsung or Google smartphones. Though Apple, Samsung and Google may compete with each other, having access to an open ecosystem means that they can get their finished device manufactured consistently and quickly.

Who can be involved in this ecosystem?

Dr. Dang: Our doors are open to everyone, and we have worked with individual innovative surgeons who are starting their own companies with a little bit of their own funds all the way to multinational, publicly-traded conglomerates.

We also have a unique program for innovators in academia. For example, our collaboration with the University of California allows UCSF faculty to innovate under a framework that lets them leverage all of PrinterPrezz’s technical resources to develop or enhance existing university IP without any artificial vendor lock-in or loss of university IP. We go even further in that our agreement with UCSF Surgical Innovations allows faculty to co-develop ideas that are at an early “napkin sketch” stage and may not be mature enough for the university IP office to file for a provisional patent. We are actively working with other university licensing offices to establish similar agreements and are happy to talk with any academic institutions that are interested in collaborating with PrinterPrezz.

We truly believe that innovation and education are synonymous. We are proud to support the OMeGA grant program, which provides orthopedic graduate medical education support without conflicts or bias. For 2019 to 2020, we have supported spine surgery and arthroplasty fellowship training programs.

You use the phrase Medifacturing™. Can you describe what it means?

Dr. Dang: Medifacturing is a word we used to emphasize that we provide an end-to-end solution for medical manufacturing, which is very different from other service bureaus. Most service bureaus don’t work on clinical timelines. You get things when they’re ready. Companies understand that patient-specific custom implants for oncologic surgery have strict deadlines, but we also understand that if a company has a group of surgeon-consultants flying in for a R&D meeting, prototypes have to be delivered on just as strict of a deadline. We understand that academic surgeons have clinical, research, administrative, teaching, family and life demands and are rarely interested in starting their own companies. Thus, they need a partner who can work with university legal teams.

Half of the founding team (and half of our employees) come from the medical world, with our PrinterPrezz physicians maintaining active clinical practices so that we understand contemporary real-world clinical challenges. While we can manufacture directly from a digital design, our team has clinical and engineering insight about something like FDA 510(k) submission and how that may affect design choices for the earliest prototypes. By manufacturing prototypes on the same machines and processes used for production and requirements for FDA, the development process moves faster. Teams could use lower-cost “prototyping” machines for minor cost savings early on, but those teams would then incur tremendous added costs and time figuring out how to translate the manufacturing process from a prototype-grade printer to one that is required for volume production.

Medifacturing is probably summed up as manufacturing expertise + clinical expertise + troubleshooting expertise + semiconductor-level precision for process and controls so that we can help our customers succeed, and succeed earlier. It’s a philosophy of saying “we’ll try” instead of saying “no, it can’t be done,” and backing it up with experience and expertise at all levels of design and manufacturing.

In our first year of business, we have on more counts that I can recall been able to do things and solve problems for customers who had previously been told that what they were asking was impossible to do.

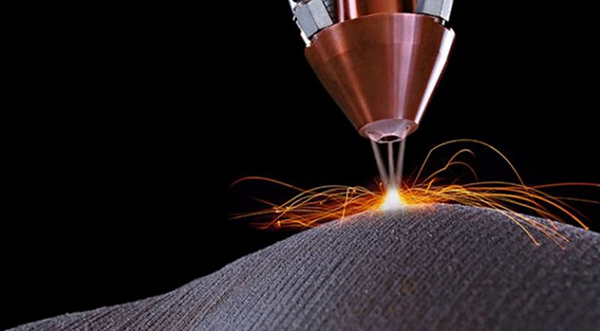

What type of additive manufacturing do you use?

Dr. Dang: The short answer is everything and the best of everything. Our entire facility is about 15,000 square feet large. We mostly talk about titanium alloy printing, since it is the most common 3D-printed implant material in orthopedic surgery and hardest to find manufacturing for. We can print in other metals, such as 316L stainless steel, cobalt chrome and others. We have flagship single-laser, multi-laser and e-beam powder bed metal printers from 3D Systems, GE and Renishaw. I always like to add the comment that we have permits for seven titanium printers, but publicly only talk about having four machines from those three vendors. We also have various resin printers, including machines from Carbon and Form labs, as well as a wide range of plastic FDM printers.

It’s always fun to talk about 3D printers in the same way that people talk about sports cars, but the driver is more important than the machine. A production environment is like a professional racing team. You need a team of drivers, a strong pit crew and a world-class engineering and manufacturing team. That’s why PrinterPrezz invests in having clinical expertise with half our team coming from the medical world. That’s why we built a manufacturing facility in one of the most expensive areas for real estate in order to have access to graduates and thought leaders from some of the top universities and medical centers in the world.

How would you describe the current state of additive manufacturing in orthopedics? How do you expect that to change in the next five years?

Dr. Dang: Additive manufacturing in orthopedics is analogous to the automotive industry in the 1960s. It’s well past the infancy or prototype stage: additively manufactured implants and instruments are available from major orthopedic device manufacturers in volume production. Innovative orthopedic residency programs such as UCSF are even providing dedicated protected didactic time for residents to learn the skills needed for pre-operative surgical planning using 3D-printed models.

But even though cars were widely available in the 1960s, cars today have benefitted from advances in safety, performance, ergonomics and efficiency. A Ferrari 250 GTO with a V12 engine from the late 1960s may be worth as much as $70 million today, but it actually has less horsepower than a well-equipped Toyota Camry of today.

In the next five years, advances in additive manufacturing will do for orthopedic surgery what 50 years of innovation did for the automotive industry.

For patients, performance and safety go hand in hand, as additive manufacturing enables new strategies to decrease risks such as aseptic loosening, stress shielding, subsidence, infection and non-union or pseudarthrosis.

Improved safety extends to the whole surgical team. Lighter instrument trays will decrease workplace strain and injury for the surgical technicians and circulating nurses and sterilization specialists.

Low-volume production capabilities enabled by additive manufacturing will allow a wider range of surgical instruments to be produced for all surgeons rather than instruments designed for the hands of a 50th percentile male surgeon. The same optimization can be applied to implants, ensuring that surgeons have options that work for patients of all sizes and shapes and bone qualities. Most exciting is that the next five years will bring further increases in efficiency for additive manufacturing, allowing these innovations to come with overall cost savings to the healthcare system rather than new technology being prohibitively expensive.

CL

Carolyn LaWell is ORTHOWORLD's Chief Content Officer. She joined ORTHOWORLD in 2012 to oversee its editorial and industry education. She previously served in editor roles at B2B magazines and newspapers.