Content sponsored by Tecomet

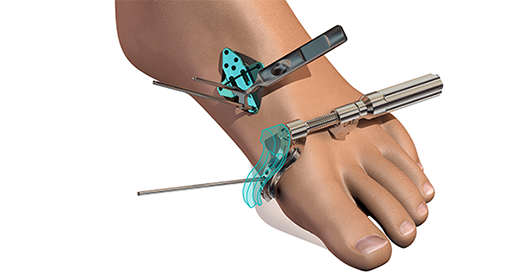

CrossRoads Extremity Systems, manufacturer of foot and ankle implants, has a unique approach in their EcoSmart Instrument Recovery Services program. Their pre-assembled kits use stainless steel and aluminum instruments that are designed to be shipped back to CrossRoads after use.

In brief, the EcoSmart process works like this: After surgery, the EcoSmart instruments are dropped into an EcoPAK container and returned to CrossRoads. There the instruments are cleaned, inspected and refurbished to like-new condition. The instruments are then packed into new kits and gamma sterilized. On a quarterly basis, CrossRoads inventories the returned instruments and cuts a rebate check to the customer based on the published prices for each instrument on EcoSmart’s list.

To gain additional perspective on the EcoSmart program, we spoke to CrossRoads Extremity Systems Co-Founder, President and CEO Vernon Hartdegen.

What led to the creation of the EcoSmart Program?

Hartdegen: There are two camps in traditional orthopedics. There’s the reusable instrument tray camp that we’re all used to, if you grew up in this industry. Kit configurations aren’t very efficient. They’re not very effective. There’s just a lot of stuff in there that never gets used.

The other camp is the world of sterile packed disposable instruments. On the disposable side of things, kit configurations are much more efficient; they’re much more streamlined. The challenge is, you end up with plastic instruments. We’ve seen surgeons struggle with certain styles of plastic instruments that just don’t hold up. You have a surgeon who has been using traditional stainless-steel orthopedic instruments, and now you’re giving him plastic.

The other downside of the disposable model is everything gets tossed. Often these kits will come pre-packed with implants and they’re not reusable. So, if you’re going to use two implants, you have to open up two kits.

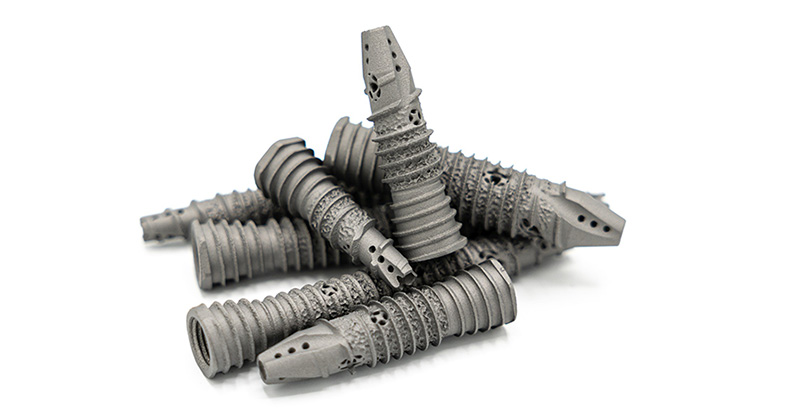

We’ve brought the two models together. We like the efficiency, the sterility assurance, the predictability of disposable kits. We love the durability of traditional instruments. We’ve taken durable, stainless-steel, well-engineered and well-designed instruments and put them into sterile packs. It’s not a sterile disposable kit, and it’s not a non-sterile reusable kit. It’s a sterile loaner kit, or sterile reusable instruments.

There’s an advantage for the hospital, ASC, surgeon, patient…everybody. You have the right drivers for the right screws; you have the right drill bits. Nothing is dull; nothing is broken. Nothing is missing, so the efficiency in the operating room is pretty flawless. It’s all there, it’s all sharp and it’s all specific to the implant you’re using. That creates an efficiency in the operating room for the surgeon, the patient and even the back table.

Because it’s gamma sterilized, it’s prepacked in small boxes, so it takes up less shelf space. The reps don’t have to get into the hospital 24 or 48 hours ahead so that the instruments get sterilized. After surgery, we collect everything and central supply doesn’t have to deal with it. Folks in central supply aren’t trying to figure out whether a driver goes with this tray or that tray. Is the drill sharp or not sharp? Sharpness is a very subjective thing. You hear stories about opening trays and finding stuff still in drill bits. With EcoSmart, they don’t have to deal with that. We just bring the quality assurance to another level.

Why don’t more OEMs go with this model?

Hartdegen: There’s an upfront investment in the kits and the tooling for the trays, but that’s not unfamiliar to anybody. What we’ve said is, if you’re going to sterile pack an implant, why hold the instruments to any less of a standard? Dirty instruments are where your infection rates come from. I think part of it is the change. Large OEMs can be risk-averse or can have difficulty making that change if they have 500 seven-tray instrument sets.

For us, foot and ankle is a nice market to start in because everything is procedure-specific. If a surgeon is doing a mid-foot reconstruction, they typically know the bones they’re going to fuse, and we can tailor our products. Some cervical spine applications, maxillofacial applications and upper extremity applications could make this approach work. We’ve had a pretty well-known hospital group approach us about the idea of helping them do this for their hips and knees.

How has CrossRoads Extremity Systems benefited from the program?

Hartdegen: As it’s evolved, we’ve learned a lot about how to design and finish instruments for the EcoSmart process. But for us, the program has helped with our margins. We get this blended moving average cost of goods that, even as we grow, we have this constant influx of instruments coming back in that we can get back into the supply chain. The unique thing is, when you think about demand and forecast, the highest volume items being used are the highest volume items coming back. Your outlier sizes don’t come back that often, because they’re not used that often. It helps with internal supply chain management

It really is patient-centric, but as you work out from the patient to the surgeon to the hospital surgical staff to the facility, and ultimately to the payors, it works out really well. It allows us to either negotiate a different pricing structure upfront with the service we provide, or it allows us to provide a rebate because we’ll buy those instruments back. We’ve taken that to a hospital or ASC and worked them into our supply chain.

For us, the biggest benefit is the uniqueness of the program. Our goal, our mission, is to make that operating room experience the best it can be. That has been the biggest impact. The satisfaction that comes from the surgeon or support staff is important to us. We’re after customer satisfaction. The products, implant-wise, do very well. We constantly hear great feedback from our surgeons and patients. Wrapping the EcoSmart service around that is really good. It gives another discussion we can have. We can talk about not just pricing on implants, but pricing on the service and how that impacts the whole episode of care.

ME

Mike Evers is a Senior Market Analyst and writer with over 15 years of experience in the medical industry, spanning cardiac rhythm management, ER coding and billing, and orthopedics. He joined ORTHOWORLD in 2018, where he provides market analysis and editorial coverage.