Business disruptions can come in many forms, some of them long-term or devastating. Hurricanes, fires, floods and other natural disasters can put operations on indefinite hold. However, myriad issues can throw a wrench into the supply chain.

When a company relies on many suppliers, each relationship needs to operate smoothly for the business to operate effectively. This is where risk management becomes vital. Having a documented process in place and knowing exactly what to do in case of all sorts of scenarios will better prepare a company for the inevitable disruption, and a more rapid restoration to productivity. If a problem occurs, the plan can be activated immediately.

“When an emergency happens, it’s hard for people to think straight,” said Todd Fewins, President of Precision Edge Surgical Products. “It’s very important to have a list of things that need to be done, so that employees can follow a process and not necessarily have to think about things in an emotional situation.”

A Formal Approach

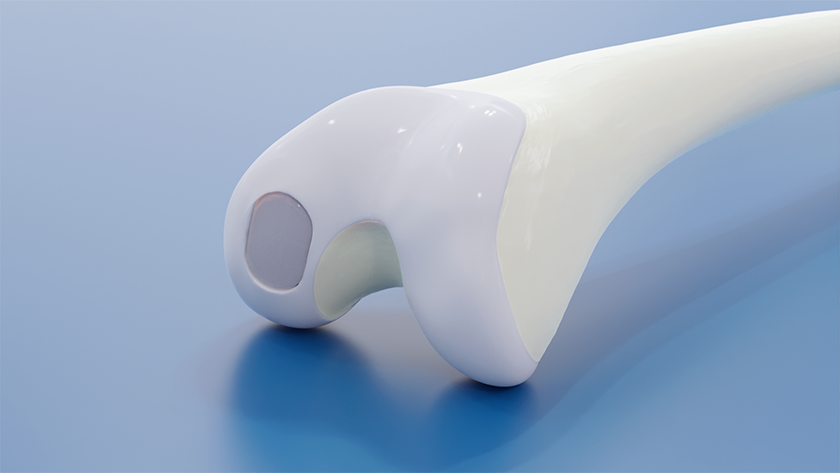

Zimmer Biomet is the second-largest orthopedic company, with $7 billion in industry revenue, +1.8% in 2018 vs. 2017. The company has struggled to perform at market growth levels in recent years, largely due to supply chain issues that stemmed from FDA Form 483s issued at their Warsaw North Campus dating back to 2016. In February 2019, Zimmer Biomet leadership noted that the company had reduced backorders and no longer considered supply to be a barrier to sales; however, they continue to execute an ongoing quality remediation plan and expect FDA reinspection by the end of 2019.

Supply chain and quality improvements—both internally and externally—are clear priorities. One Zimmer Biomet initiative is a continual formal Supplier Risk Management Program, which the company launched in late 2016.

To protect their business and their customers, Zimmer Biomet recognized the need for a full-scale risk management program that extended beyond their own company. With a complex supply chain—and several suppliers providing critical components or services—a single disruption to a supplier’s operations could upset business continuity for Zimmer Biomet.

“We put formalization to the way that Zimmer Biomet wanted to manage risk, moving forward,” said John Manning, Associate Director Sourcing Compliance and Process Improvement for Zimmer Biomet. “We’re working toward a fully resilient supply chain, looking to minimize or mitigate business disruptions.”

The program’s intent is to work with as many suppliers as possible to identify risks, assess current risk management plans in place and recommend improvements or contingencies to eliminate or reduce the most crippling disruptions. Zimmer Biomet’s approach is focused on creating a sustainable resiliency program that permeates their supply base, while making it a priority as part of their internal culture.

The first year of the program was spent establishing the basics, such as executive sponsorship, developing procedures of how they’d manage the process, identifying the risks and setting the strategies, Manning said. Over time, the program has matured.

“The team members have become more comfortable with the process, and we’ve tweaked a few things here and there,” he said. “Identifying risks has slowed down, but mitigation of risk has really sped up.”

The Process

The categories that Zimmer Biomet focus on in their program are single- and sole-source supplier risk, business continuity risk and financial risk. They’re looking at third-party suppliers worldwide that produce critical products in all business segments, and they rank their priorities based on risk to revenue.

The process begins with a questionnaire to determine how the supplier is currently handling risk management. If a plan is already in place, Zimmer Biomet will advise on ways to evolve or reinforce it. If no plan is in place, they work with the supplier to put best practices into place and formalize their program, either directly or by referring them to additional resources.

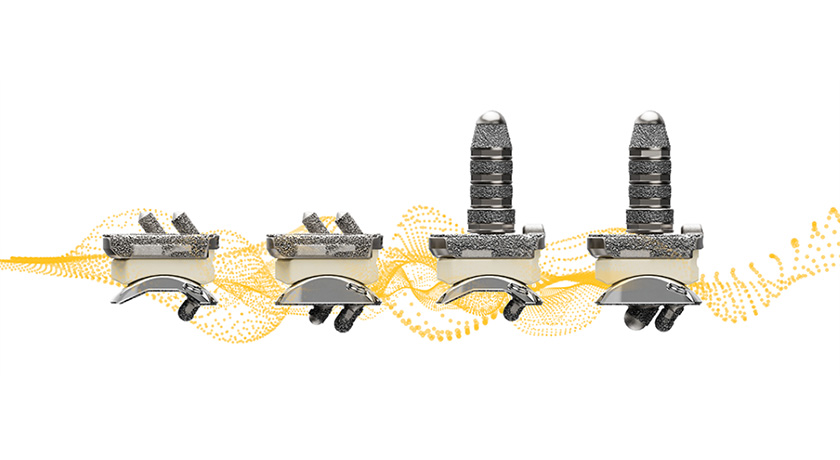

Precision Edge is one supplier that works with Zimmer Biomet, providing various cutting and non-cutting tool instruments for several divisions. Precision Edge has had a business continuity plan in place since 2010, and has updated it over time.

“The primary reason to have a formalized system in place is to make sure that our customers are protected and make sure that they’ve got supply,” Fewins said, emphasizing the importance of having surgeons armed with the tools needed to perform a successful procedure for the patient. “Some of the stuff we do is life-changing for patients, and we want to make sure that we protect the end-user and do it in a timely fashion for when the surgery is needed.”

In addition, from an internal perspective, it’s important to have a formal program in place in order to protect the company’s sales channel and profitability, Fewins said. “If something major were to happen and we were to shut down, obviously that would have a huge impact on our ability to sell products to our customers, maintain a good healthy position and stay in business.”

Zimmer Biomet reached out to Precision Edge about two years ago in an effort to ensure a robust supply chain and make sure that manufacturing redundancies were in place. To begin, Zimmer Biomet requested copies of Precision Edge’s business continuity plan, reviewed these and provided feedback for improvements. The dialogue resulted in Precision Edge updating its plan to include timing based on a type of event that could occur.

“It was very helpful for us because that helped us understand what needs to happen in a six-hour timeframe from the point of the event, to 12 hours, to 24 hours—really all the way out to the point that the disruption is no longer a disruption,” Fewins said.

Over the past two years, Zimmer Biomet has seen suppliers consolidate while participating in the program. When that happens, it adds more operations and a larger footprint for the company to look at.

“We work with that supplier, and it helps to incorporate that into a larger discussion with the suppliers that now fall under a new business plan,” Manning said. “With consolidation, two companies are trying to fit under one program, so we try to steer them toward the better one. Sometimes it actually increases flexibility, because there are fewer single-source suppliers in the mix.”

A Team Effort

Having a detailed, formalized program for supplier risk management takes a lot of people moving in the same direction. Zimmer Biomet secured executive sponsorship at the vice president level of sourcing, which continues to drive the program and keeps the focus and importance of the program top-of-mind with team members. There are approximately 40 people involved in their supplier risk management program monthly meetings, with dozens more indirectly involved.

“Executive sponsorship is essential,” Manning said. “We’ve had great support from our leadership; cross-functionally, everyone sees the value in the program. It’s part of the company culture to embrace the change; it is effective, it does work.”

To keep everyone involved and increase buy-in from the team, Zimmer Biomet holds monthly meetings to discuss high-risk suppliers as well as monthly report-out meetings to cross-functional teams.

“Risk programs are really a part of everyone’s responsibility,” Manning said. “Everyone is proactive and aware—if you know something, tell someone. Identify the threats to our business continuity.”

That team buy-in has to translate to the suppliers as well. Fewins said that facility engineers in each of Precision Edge’s buildings lead the efforts. They are responsible for an annual review of the risk management program, taking input throughout the year and updating it.

“The business continuity plan document is broken up by function, so each functional area has input to the annual updates,” Fewins said. “It’s a team effort to make sure that it’s fully maintained to match our business.”

The Metrics for Effectiveness

More than two years since establishing a formal program, Zimmer Biomet’s supplier risk management initiative continues to evolve.

They categorize programs into three buckets: high-, medium- and low-risk operations. Each month, they meet with high-risk suppliers to make sure that project plans are implemented and resource needs are met. Leadership members are on those calls.

The team measures the effectiveness of the program based on metrics that include completed projects vs. what’s been identified (meaning that the risk has been eliminated), as well as the reduction of high-risk projects.

“We’ve identified more than 425-450 individual areas of risks since we’ve started,” Manning said. “We’ve eliminated the risk entirely for more than half of those. We’ve reduced high-risk operations to about 50% of what they were two years ago—the high-risk areas that are left are ones that are longer and more complex. We expect that 2019 is going to be a big year for us in eliminating high risk. We expect to have 90% of our high-risk projects mitigated,” Manning said.

Zimmer Biomet has learned best practices along the way that help refine their process.

“One size does not fit all. What works with one supplier, can’t be cookie-cut to another supplier. Different suppliers require different mitigation strategies,” Manning said. “We listen to the suppliers regarding solutions; they understand their business very well. The ultimate goal is to mitigate the risk, and it doesn’t matter what tools you use to get there.”

Once the plans are in place with suppliers, they continue to advise on ways that each company can improve, as well as how to work with their suppliers in a similar way to reduce risk. The program is already seeing results with Zimmer Biomet’s suppliers.

“We’ve definitely looked at where we need to have redundancies,” Fewins said. “Even with our suppliers, we’ve looked at them from a redundancy and risk perspective to make sure that we’ve got alternative suppliers set up in case something does happen. Another suggestion from our meeting with Zimmer Biomet was to make sure that we’ve done a thorough job with our supply base to make sure they have plans in place.”

As Zimmer Biomet refines their program and recommends process improvements for their suppliers, they continue to seek out ways to ensure that the process is working, and to address any situation that isn’t.

“Their most recent feedback to us is the next stage: How do we test to make sure our business continuity plan is actually effective?” Fewins said. “To have one is one thing, but to actually test it and make sure it’s functioning and able to work and do as expected is our next stage of evaluation.”

HT

Heather Tunstall is a BONEZONE Contributor.