Content sponsored by Orchid Orthopedic Solutions

For those of us working in the orthopedic industry, our objective is simple: keep the world in motion. Whether we’re manufacturing hip, knee or spine implants, we’re profoundly impacting someone’s life by restoring their mobility. Simply put, to ensure that a patient has the opportunity to live a longer active life, an implant procedure must be successful. From rapid bone in-growth to wear resistance and antimicrobial properties, the role of orthopedic coatings in the success of a procedure is vital.

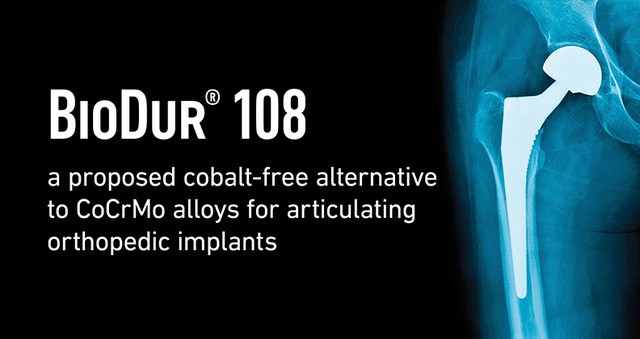

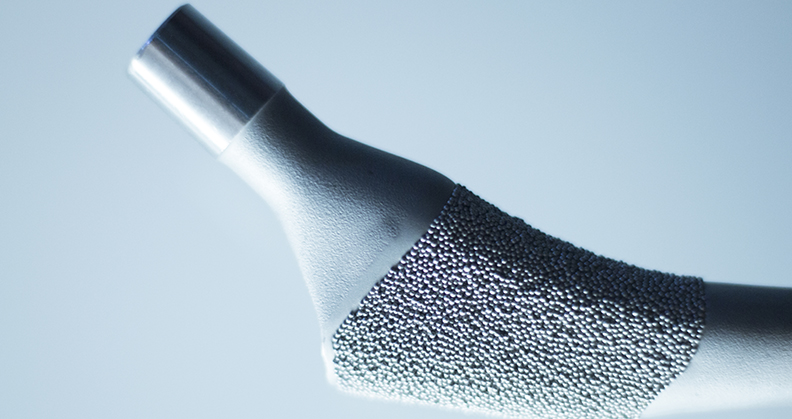

A strong bone fixation between the host bone and implant is crucial for the longevity of the implant. If the living bone doesn’t accept the implant, future complications and hospital returns are the risk. Utilizing bone in-growth coatings can prevent this. Coatings can also be used for bearing surfaces, providing the benefits of reduced friction and corrosion. The life cycle of the device may be extended and prevent the patient from experiencing discomfort when the device is in use.

Two popular coatings used today are sintered bead and plasma spray technologies. Sintered coatings have an extensive clinical history, dating back to the 1970s. Plasma spray coating types include titanium plasma spray. Advantages of this coating include its open porosity and rough topography, which can help bone attachment, called osseointegration.

While the orthopedic coating market is primed for growth, it still faces some challenges. New coating techniques must undergo a lengthy and rigorous validation protocol, making it difficult to get new technologies to market. There also are no set guidelines available for coatings, and development of testing methods for new coatings could take a considerable amount of time.

Despite the potential roadblocks in the commercialization of orthopedic coatings, new ones are in development. What can we expect to see in the future? For instance, there are antimicrobial coatings, which help fight infection. These reduce post-operative infections by making the coating surface incompatible to harmful microorganisms. Anti-wear coatings are also emerging, which enable implants to last longer. In terms of new porous coating technology, additive manufacturing application or 3D printing is being utilized to create implants with integral bone in-growth structures.

Just like an implant supports a patient, orthopedic coatings support an implant. As you read through this coating-focused issue of BONEZONE, I hope that you are reminded of how rewarding it is to work in the orthopedic industry. Whether we are designing, manufacturing, coating or performing the implant procedure, we’re all contributing to something bigger: keeping the world in motion.

Jerry Jurkiewicz

Chief Executive Officer

Orchid Orthopedic Solutions