Inertia exists across numerous industries. Medical device manufacturers aren’t the only companies imbued with a sense that, “If we just do things the way we’ve always done them, we’ll be fine.” However, in an age of tightening healthcare budgets and the potential for tough choices to be handed down by governments, healthcare providers and consumers, the firms that survive will be those with the courage to adopt leaner and faster methods that improve quality while cutting costs. One such opportunity lies in different inspection methods.

The medical device industry has been abuzz with discussion of non-contact inspection methods, particularly White Light Scanning (WLS) and Computer Aided Inspection (CAI). This article will outline the technology that underlies WLS/CAI and explain the technique’s ability to:

1. Increase confidence

2. Decrease time to market (TTM)

3. Help make better parts faster

4. Reduce legal exposure through understanding the process capability in a comprehensive format that is readily comprehended by humans

Traditional inspection methods are closely bound to a FIT –> FORM –>FUNCTION paradigm in which a prototype or sample part is first compared to specified dimensions and GD&T (Geometric Dimensioning & Tolerances) callouts. After a precision manufactured part successfully passes through this first “logic gate,” the surface profile is compared to the nominal geometry from the Computer Aided Design (CAD) model. The part’s functionality is traditionally considered as the final criterion for compliance.

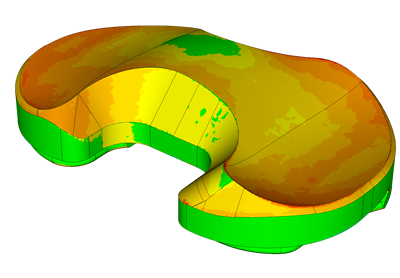

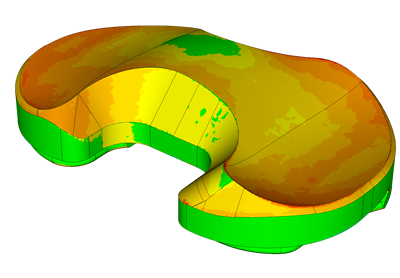

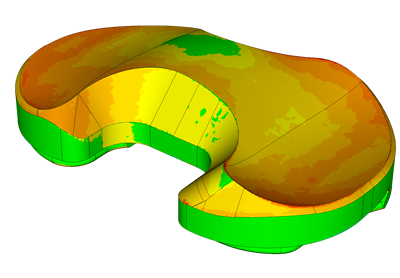

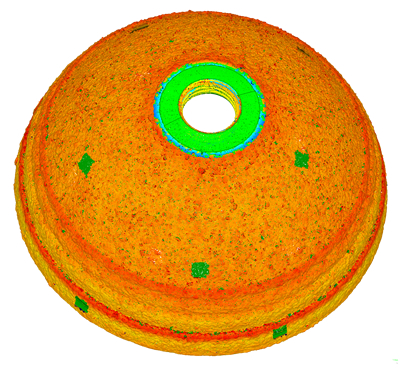

With proper preparation, WLS technology can be applied to any material or surface finish, including translucent polymeric bearings. This color-plot illustrates the true part geometry relative to the nominal CAD highlighting GD&T profiles, as a precursor to complete dimensional inspection to the blueprint.

Utilizing technologies like WLS that can gather huge amounts of part geometry data very quickly, CAI can invert and expedite this paradigm. As will be explained, prototypes and product development iterations can often be reduced substantially when a part’s geometry is studied first. Quite often, geometric anomalies can be detected that would have gone unnoticed or unexplained under the traditional inspection paradigm. Sometimes these anomalies are found too late: in the marketplace.

By focusing on the resolution of geometric anomalies rather than worrying about dimensional nonconformances, product development can be quite effectively streamlined. Excessively tight tolerances can be loosened, irregularities in the process can be removed or corrected and functionality can be improved, all while increasing speed and decreasing cost.

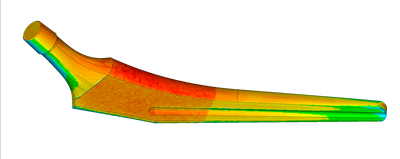

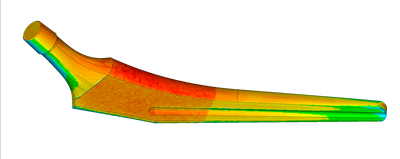

Precision CNC machined parts are exceptionally well illustrated and inspected. Even individual cutting-edge profiles can be evaluated for any level of detailed inspection, or just pass/fail, as desired.

The Inadequacy of 20th Century Inspection Methods

Medical device inspection is still largely dominated by decades-old mechanical coordinate measuring machines (CMMs), which utilize an articulating robotic arm to calculate the location of a touch probe to test individual points, one at a time, along the surface contour of an object. CMMs are severely limited with respect to speed, comprehensiveness and accuracy. According to studies, the typical CMM output report is mis-interpreted as much as 20 percent of the time due to its table of coordinate numbers, which by itself communicates geometry details poorly.

Not without a small degree of justification, WLS has acquired a reputation among medical device manufacturers for being tricky to use and for turning out reams of incomprehensible data. Just as with older inspection technologies such as CMMs, WLS/CAI requires expertise, built on experience, to optimize the results and make the most of its incredible potential.

WLS is at once both sublime in its simplicity and elegant in its precision. A light projects parallel raster lines across a part surface. (Pure white light is, of course, not a color in itself but a shade generated by the simultaneous sensation of colors across the spectrum.) Each of the discrete colors generates a fringe pattern; the white light interferogram comprising these fringe patterns is rich in surface point data. A waveform calculation is performed on the point data at each pixel to generate a complete three-dimensional “data cloud” digital surface map of the part.

The full 3D geometry in CAI digital analysis provides easily-understood coating thickness and uniformity information across the entire part surface. Digital cross-sections show surface roughness anywhere on the part, and surface finish RMA can be calculated from ISO formulas.

Gauge Repeatability and Reproducibility (Gauge R&R) studies have shown that the digitized surface data point cloud is accurate up to a sensitivity of 0.000004” (100 nm) in carefully implemented environments. A sufficient number of part surface area scans are taken so that the scans can be merged into a watertight polygonized mesh encompassing the surface of the entire part. Computational geometry is then applied to the polygonized mesh to generate a postprocessed stereolithographic solid that can be topologically compared against a parametric model. A projected image of the model can then be color-coded to demonstrate which locations on the part’s surface have dimensional errors beyond applied tolerance bands from nominal CAD.

Where WLS/CAI really rises above CMM analysis is in its surface area point density that can result in a clear and coherent image of the surface geometry. In extreme cases, WLS can yield watertight scans comprising hundreds of millions of points, while a complex CMM program might yield a few hundred or a very few thousand touch-data points. In the most sophisticated analysis, WLS surface images can be analyzed statistically using MINITAB or a similar software package, uncovering systemic deviations in the manufacturing process and enabling the customer to reassess and more rapidly optimize the production process.

But even a cursory glance at the color plot has enabled some medical device manufacturers to intuitively grasp the causes of bad measurements that remained mysterious or unnoticed while studying tabular CMM output. The customer is offered a visual presentation of the results in the form of an executive summary. The customer can reassess the phases of manufacture to determine where the error arose and apply the measurement technology early in the manufacturing process stages, thus identifying and resolving problems before they compound and incur more expense by further production processing.

In comparison to handheld laser scans, WLS also literally shines. Laser scanners, with which WLS is often confused, typically claim an accuracy of 0.002” to 0.005” – inferior to typical white light scanners by some orders of magnitude. Laser scans are only capable of assessing the grossest of deviations. Even though laser scans offer greater point density than CMMs, their inaccuracy makes them unsuitable for Statistical Process Control (SPC)-based process analysis, especially in precision manufacturing.

The combination of greater accuracy, higher comprehensiveness, visual geometric conformance surface plots and SPC to sniff out systemic deviations is well-established in industries, such as aerospace, automotive and industrial gas turbine manufacturing, that already make heavy use of WLS/CAI. Firms that understand its merits can dramatically expedite the process of bringing their products to market — weeks or months ahead of their competitors and at a reduced cost.

The Wow! Factor: The Pratt & Whitney F135

Pratt & Whitney’s use of WLS/CAI in developing the F135 jet engine, used in the F-35 Lightning II single-engine strike fighter, offers precision manufacturing insights relevant to the medical device industry. Among the F135’s impressive roster of “mosts” and “firsts” is this gem: It’s the first military jet engine in history to be delivered both on time and under budget.

Among the F135’s impressive roster of “mosts” and “firsts” is this gem: It’s the first military jet engine in history to be delivered both on time and under budget.

The F135 was the first gas turbine engine to be designed and built using WLS/CAI technology from the ground up – that is, from the early conceptual stages all the way through to durability testing.

By knowing the entire geometry of every component, via accurate and thorough WLS/CAI, the F135 could be brought in on schedule and budget. But the real “Wow!” factor emerges when we take a closer look at performance and durability.

The F135 is the most powerful gas turbine engine ever built, offering 43,000 pounds of thrust. It represents the first time that a production-ready, stealthy, short take-off vertical landing-capable aircraft has flown supersonic.

In addition to being the most powerful jet engine ever built, the F135 is also the most durable. Since the “wear” on an engine is a complex phenomenon that depends on throttle movement and acceleration/deceleration, the Air Force Technical Institute developed a unit of measurement called the Total Accumulation Cycle (TAC). Service life is based on an estimate of how many TACs an engine can tolerate between overhauls.

The F135 test engine was run in conditions simulating flight at 30,000 feet and Mach 1.5, with the turbine at 50°F above melting temperature and the high and low pressure turbine spools spinning at 100 percent. Inspections revealed no subsequent distress and no required maintenance.

The targeted service life was 8,000 TACs, but the initial service test went all the way to 8,700 TACs. Upon disassembly and inspection, the components showed no signs of breakdown. As a result of the F135’s unprecedented triumph in durability, monies that would have been used to cover program overages (of which there were none) are now being used to fund further durability testing (all the way to engine failure) for the U.S. Navy.

This incredible achievement was possible because Pratt & Whitney was able to absolutely know the entire surface geometry – not only of every vane and blade, but of every nut and bolt. As Pratt’s competitors, Rolls-Royce and General Electric, have been unable to develop an operational alternative to the F135, Pratt is likely to remain the sole supplier of engines for the F-35 fighter – a market estimated at $100 billion. That’s a compelling return on Pratt’s CAI investment of less than $5 million.

Paradigm Shift

Implant part families vary bilaterally and according to patient age, size and medical needs. CMM measurements, currently prevalent in the medical device industry, are too few and too primitive for a sophisticated computational analysis. But when engineers see deviations depicted accurately and in full color — deviations that might have eluded them for years — they will realize that they can pinpoint the exact source of an error and thus, attack/resolve accordingly. Then they can expand the strategy across a whole part family, and build quality in to the product by starting the comprehensive process and result assessment earlier in the manufacturing process stages.

With experience, it’s possible to use this information to optimize processes quickly and comprehensively. The intellectually rigorous approach of aerospace firms and other precision manufacturers that utilize WLS/CAI on a large scale has yielded a new inspection and product development paradigm that largely inverts the traditional FIT –>FORM –>FUNCTION approach:

1. Gather information through CAI.

2. Study data for problems, trends and surprises.

3. Gain meaningful insights into process capabilities and limits.

4. Revise design parameters to line up with realistic process limits. Extravagantly tight tolerances are a self-defeating proposition … especially when involving regulatory agencies like FDA.

5. Drive insights back into manufacturing to shrink process limits and create specific production measurement plans to track areas of concern vis-à-vis process capability and limits.

6. Continue to gather data periodically. Trust data from advanced measurement techniques, and learn from what it tells you – good or bad.

7. Expand focus to tooling and other upstream processes in order to have more control sooner, and catch problems before they grow or compound.

Dynamic visualization – the practice of driving WLS/CAI insights back into the manufacturing process – has been shown to reduce the dimensional inspection report review time by 90 percent, with far greater confidence in the results. For this reason, some of the most sophisticated global players in the medical device industry have overhauled the way they dimension their models and blueprints to conform to and leverage this new full geometric understanding.

Medical device manufacturers, by applying their own brand of intellectual rigor, can gain a competitive edge by adapting the new paradigm to their own processes, allowing for faster decision making, cycle reduction and ultimately, significantly quicker time to market. In addition to straightforward process streamlining, some manufacturers are discovering that WLS/CAI offers them a defense against longstanding legal problems.

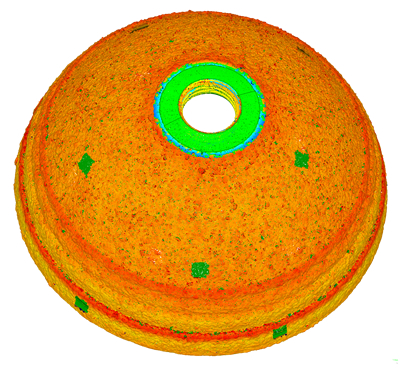

Finished machining accuracy and bone-ingrowth coating thickness are shown clearly, so product engineers can confidently assess processes and use this information to make specific adjustments.

The WLS provides 1,000x the data points of traditional measurement systems, revealing much more information about the result of the manufacturing process. When tested, there is perfect correlation between the overlapping data points from measurement systems.

An example arises from an inspection that compared an new implant to a used implant and the CAD model. The inspection report was used in legal defense in a class action lawsuit, demonstrating that the issue was not the manufacturer’s fault. The strength of the technical inspection, combined with the easily understood visualization, were critical in allowing this client to win its case. Through improved process confidence, WLS/CAI can help OEMs reduce legal exposure and costs of doing business.

A seismic shift in inspection technology is taking hold in product development, and given the intense competition and uncertain future in the medical device industry, this opportunity can’t come at a better time. By bolstering confidence in processes and products, manufacturers can finally:

1. Increase confidence by inspecting fewer parts, better

2. Replace the antiquated practice of 100 percent part inspection with SPC

3. Decrease time to market TTM for new products 25 percent to 50 percent

4. Decrease revision time for existing products 50 percent to 80 percent

5. Reimagine industry standards for quality, safety, reliability and durability

6. Drive new standards for regulatory compliance

7. Reduce legal exposure

8. Solve engineering problems that have vexed the industry for years

The bottom line remains cost savings. Aerospace, automotive and industrial gas turbine manufacturers, to say nothing of the large public art and sculpture enterprises that have made use of the technology, are less bound by constraints of time than are medical device manufacturers. And they’re generally a little less beleaguered by costly legal assaults, though no one is entirely immune.

However, even those industries have perceived the direct bottom-line benefit of faster product development. How much more, then, have medical device manufacturers to gain by embracing 21st century inspection technologies? Clearly, the benefits vary among OEM and supply chain companies, and they are substantial across the industry.

For the first time, White Light Scanning and Computer Aided Inspection make aerospace rigor available to the medical implant and device industry. The sole remaining question: how much less are you willing to spend to make aerospace rigor your own?

ALL SYSTEMS GO.

For further information:

1. en.wikipedia.org/wiki/White_light_scanner

2. www.level3inspection.com/files/SmartGR&R.pdf

Bill Greene is a co-founding Director of Level 3 Inspection LLC and is leading the Strategy Development efforts while serving as CEO and VP Business Develoment for the company. Based on his Metallurgical Engineering and Economics educational foundation, he has focused his career on introducing and delivering business-favoring technology solutions to major industry clientele. Having engineered and automated most manufacturing processes, Mr. Greene is well versed in the needs, opportunities and ROI requirements of modern manufacturing enterprises. He can be reached by phone at 561.775.7911 or by email at