Renishaw, a precision engineering and manufacturing technologies company, has announced InfiniAM Spectral, a new additive manufacturing (AM) process monitoring software.

Developed for use on Renishaw systems, the software package helps AM users gain a greater understanding of their processes and overcome the difficulties with AM in critical applications, process stability and part quality, according to the company. InfiniAM Spectral is part of a family of products that help users capture, evaluate, present and store process data from Renishaw laser powder-bed fusion technologies.

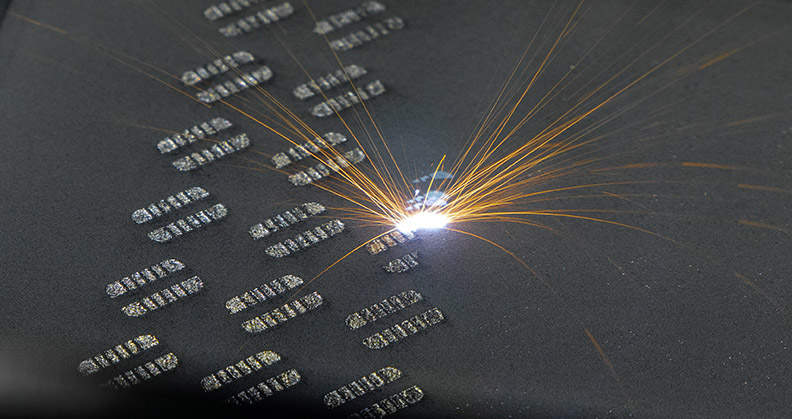

The new software offers two measurement functions in the sensor modules, according to Renishaw. The first module, LaserVIEW, uses a photosensitive diode to measure the intensity of the laser energy. The second module, MeltVIEW, captures emissions from the melt pool in the near-infrared and infrared spectral ranges.

MeltVIEW and LaserVIEW stream data across a conventional computer network on a layer-by-layer basis, so manufacturers can analyze process monitoring data in real-time. As the build progresses, data is rendered live in 3D for viewing in InfiniAM Spectral. The engineer can compare data from each sensor to identify any deviations, which may indicate the presence of anomalies that could lead to defects.

Source: Renishaw