All medical devices must be tested. However, the varied aspects of device testing can be unfamiliar ground, and standards are often vague guidelines, open to interpretation. OEMs of all sizes are left to question, what is the best test method? How many cycles do we perform? What loading profiles must we consider?

You may even wonder, should we contract out this testing?

Based on your company’s size and internal resources, in-house testing may not be feasible. However, Justin Metcalf, Director of Engineering at MED Institute, suggests that companies that have the bandwidth and expertise to control their own testing should do so. The benefits are numerous: ultimate control of resources and time, and the ability to keep the key stakeholders, like project managers, intimately involved throughout the process. If you must contract out some or all of your testing, consider the following factors when assessing partners.

Regulatory Expertise and the Ability to Advise

If you seek to outsource, Metcalf urges you to be aware: not all contract labs have a full understanding of the regulatory approval process—the origins of acceptance criteria, for example, and ways that engineers ultimately contribute to device approval.

He elaborated that, while a lab may have a particular capability—like device fatigue testing, for instance—it may lack any experience of participating in the clinical feedback loop that makes that analysis relevant. Thus, the burden of understanding the tests and subsequent results may still rest on OEMs. This shouldn’t pose a problem if your company has a clear understanding of what testing needs to be done with your device, but it’s a different story if the device is new to your team.

It’s important as well to understand the lab’s full range of expertise, and that means examining their accreditations (like ISO 17025) and asking about their history in testing specific devices. You’ll want to know how extensively the lab has worked with devices similar to yours, and inquire about the necessity of each test for FDA approval.

OEMs that lack internal testing knowledge may also need guidance on tests that are needed to satisfy FDA standards.

Metcalf says that experienced external test labs should be able to show expertise in dealing with FDA. That means offering information on what tests they have performed in the past, what has achieved regulatory approval from FDA and international regulatory bodies, and what has served as a barrier to approval.

Many firms also participate in FDA research agreements or sit on industry groups with FDA members, gaining knowledge to maintain an open line of communication about what the Agency may require for device testing in the future. In some cases, external firms can even facilitate conversation between FDA and an OEM.

Finally, some firms believe that using an external lab can reduce the impression of bias during regulatory submissions.

Kent Vilendrer, Founder, President and CEO of Medical Device Testing Services, says, “Quality protocols that are backed by certification are important both to upper management, as a basis of business decisions, and to regulatory agencies that will be evaluating the data.”

Confidentiality

Another drawback to outsourcing is the possibility of leaked proprietary information. Vilendrer points out that some labs do not have measures in place to keep your data private.

“Confidentiality is a big consideration. Your intellectual property is a significant component of your competitive advantage,” he says. “The device design, test protocol and data generated need to be kept confidential. Does the test lab you are considering have a quality policy that deals directly with confidentiality?”

Metcalf echoed those sentiments, adding that when you share information on your device’s acceptance criteria, you may be unintentionally sharing that with the entire device testing community. Non-disclosure agreements (NDA) are of paramount importance; you should be sure that your contract testing partner either provides an NDA or is willing to sign one.

Cost

Many OEMs that stay in-house believe there is a benefit of cost savings. That may be true, but the amount of savings depends upon myriad factors. Direct comparisons between in-house testing costs and contracting to an external firm can be complicated. The cost of performing an outside test is easily obtained by requesting a quote, but be mindful that in-house testing costs have more parameters to consider:

- Will you need to purchase equipment and accessories (such as fixtures, sensors, etc.)?

- Will you need to design and fabricate parts, such as fixtures?

- What are the costs of using your own facilities and equipment?

- What are the costs of technicians’ and engineers’ time spent training on and calibrating the equipment, setting up and performing the test, then performing data analysis and writing reports?

In addition to these more obvious costs, other factors need to be considered, such as schedule delays and their financial impact. There is also the possibility of testing errors and repeat tests.

Startups and OEMs that don’t have testing capabilities save on the cost of investing in equipment, as well as personnel and training to run and maintain the equipment, when they contract out. It may make financial sense to invest in testing equipment later, as your company grows.

Expertise-On-Demand

“Complexity of the test is usually a key reason to select a contract test lab,” Vilendrer says. “Tests can range from basic materials characterization and feasibility for proof of concept, to full device fatigue-to-success for FDA submissions or supplementary data needed based on device performance in patients.”

As an example, Vilendrer says that if your device includes metal ions that may be released post-op, your device may require metal ion analysis. If your device includes an additively-manufactured coating, and runs the risk of shedding particles post-implantation, it may require a particle capture and analysis. If your internal lab does not have experience with those tests, it makes sense to contact test labs.

“Labs are generally set up to run specific standardized tests, quickly and efficiently, with validated methods,” Metcalf says. “You, on the other hand, may want to focus on manufacturing validations, suppliers and second-tier suppliers. Having the assurance that your device is being tested as quickly and efficiently as possible should set you at ease.”

For companies that have testing frames and in-house personnel, contracting out can still make sense in certain situations. If you’re working with a new material or coating, like a nanostructure surface, your internal labs may not be equipped to handle those testing needs. An external lab could alleviate the cost of research and training of your technicians and engineers, and save time in your validation and verification process.

The notion of saving the OEM time and money during the testing phase was a sentiment shared among the experts I consulted. Dawn Lissy, Founder, President and CEO of Empirical Testing, put forth that OEMs could instead focus on ensuring that they had selected the best vendor for compiling a regulatory submission, or the best contract manufacturer, or other aspects of product design and development—while testing was in the hands of an accredited lab.

Space

One major appeal of using a properly equipped external lab is the efficiency that it can bring to your process. When it was founded, Empirical had three test frames and a queue of about four weeks. The company now has 30 test frames and a wait time of about one week.

For OEMs interested in line extensions, contract labs offer the benefit of overflow testing frames. For example, prior to founding Empirical, Dawn Lissy worked as a product development engineer for an OEM that performed internal testing, where she frequently grappled with resource limits.

She says that even if her projects were considered to be lower-priority, and were not given the same internal resources as other products, she still had to meet specific project requirements and milestones. Thus, she needed to work with management to determine the best external resources for her project and find the most efficient, cost-effective way to accomplish goals.

“Many of our clients have anywhere from one to 30 test frames in-house. A company with up to three frames generally uses those for product development testing, and outsources the rest,” she says. “If a company has 30 frames, then they’ll use external labs for overflow. They may choose an external resource for the experience level working with a specific test, too.”

Conclusion

For every company, the decision to contract out boils down to a combination of cost-analysis, company culture and philosophy. Consider confidentiality agreements, number of test frames and queue time, as well as your potential lab’s relationship with FDA.

Orthopaedics is a small world, and most of the resources with whom I spoke suggest starting with your referral base for outsourcing suggestions. From there, examine the testing lab’s experience. Ask about the history of their engineers, and their working relationship with FDA. Determine whether or not the lab is accredited.

Ultimately, if you have the expertise and the wherewithal to keep your testing in-house, do. You’ll have full control of the testing process. If you’re dealing with a complex device that is new to your team, lack the requisite internal resources or simply need overflow testing, an external source may be your most effective option.

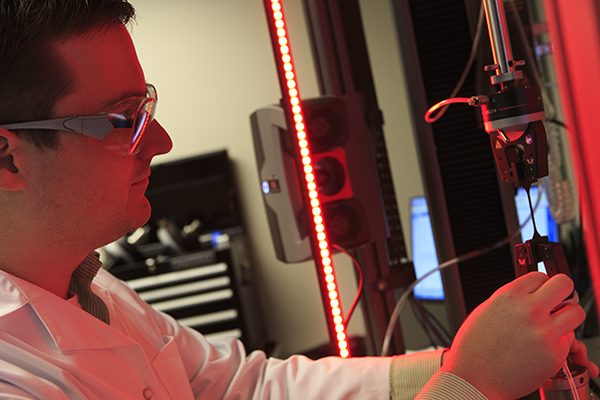

Photos Courtesy of Empirical Testing, MED Institute and Medical Device Testing Services

Questions? Email Julie Vetalice.