Noxilizer, a sterilization company with a focus on advancing the NO2-based sterilization process for medical device manufacturers, announced FDA 510(k) clearance for a medical device terminally sterilized using Noxilizer’s nitrogen dioxide sterilization process.

With this clearance, Noxilizer has established a pathway to 510(k) clearance for nitrogen dioxide sterilized devices in the industrial medical device market.

“Receiving a FDA clearance marks a pivotal milestone for Noxilizer,” says Lawrence Bruder, Noxilizer CEO. “This clearance confirms that nitrogen dioxide sterilization is another option for companies – especially for those products, like prefilled syringes, drug-delivery systems and medical devices — that face challenges with ethylene oxide, gamma radiation or other conventional sterilization methods.”

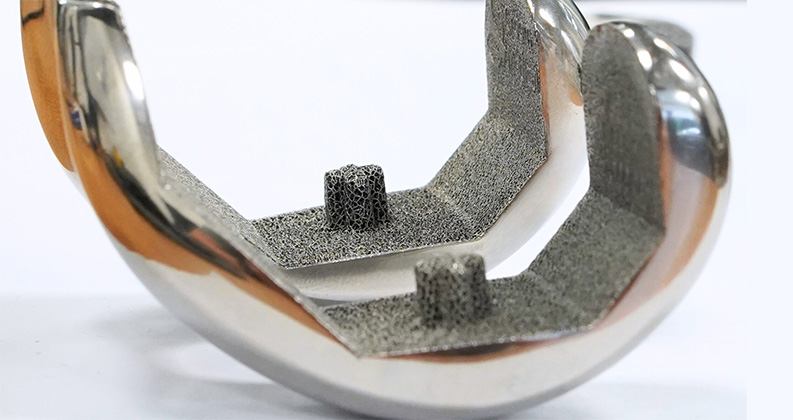

Nitrogen dioxide gas sterilization sterilizes at ultra-low temperature (10-30°C) and functions with or without vacuum and humidity, important factors for a growing number of biotech drugs and temperature-sensitive medical devices. Noxilizer’s nitrogen dioxide sterilization also allows companies to safely bring sterilization back in-house, greatly reducing process time, leading to turnaround times of 2-3 days and operational cost savings of 50% or more.

Source: Noxilizer

With UDI regulations exerting pressure on the industry to move toward more sterilized products, companies are looking for cost-effective and innovative ways to sterilize their devices.

“We’ve seen a considerable push to move from hospital-sterilized product to single-use terminally sterilized devices, taking things that normally would be autoclaved at a hospital and instead providing that device directly to the hospital, already packaged and sterilized,” says Brian Nissen, Principal Project Engineer at Quality Tech Services.