Design for manufacturability (DFM) is an essential element to the success of new devices from a standpoint of time and cost. Designs must be created with manufacturing in mind, before the design is locked down, to mitigate areas in production that would drive up costs and delay product launch. However, device companies struggle with matching internal expectations around timelines and budgets with external manufacturing expertise.

One way to tackle DFM is to partner early, right at the product’s concept, with a manufacturer to address potential problems with the design before production. Selecting a manufacturing partner early rather than shopping around for the best manufacturing price once a design is finalized can actually net more savings in the long run, by giving contract manufacturers a chance to identify where the design can be optimized for cost-effective and timely production.

“ [OEMs] want to freeze the design, get multiple bids for the lowest cost and then choose a supplier,” says Nick Ouwerkerk, Senior Project Manager at Cadence. “That means manufacturers have to quote parts that are two to three times more expensive than if they were done with DFM in mind. Saving ten percent on the bidding process leaves about two times higher cost than what the part should have been if done in a different way. But, the DFM process would add time for the design team to iterate in that phase. They want to rush the design to get the product in the market sooner, to gain revenue. The revenue gained is good, but at a cost of downstream revenue that is lost.”

This early collaboration involves a strong relationship with your manufacturing partner.

“We give priority in our scheduling to customers willing to [partner early] with us,” says Jeff Thornburgh, Co-Owner of Precision Medical Technologies. “For the five to ten percent they’re going to save by shopping at four different places, we can save them 20 percent by being involved earlier. Then it becomes a partnership. We become committed much earlier; we feel like we’re part of the launch, so to speak. We’ve got some skin in the game.”

Besides the emphasis on partnering early and forming solid relationships with suppliers, design engineers will be well-served if they familiarize themselves with certain manufacturing considerations. Designs best suited for manufacturing are not necessarily simpler in construct, but they do consider manufacturing implications related to feature size, tolerance and inspection.

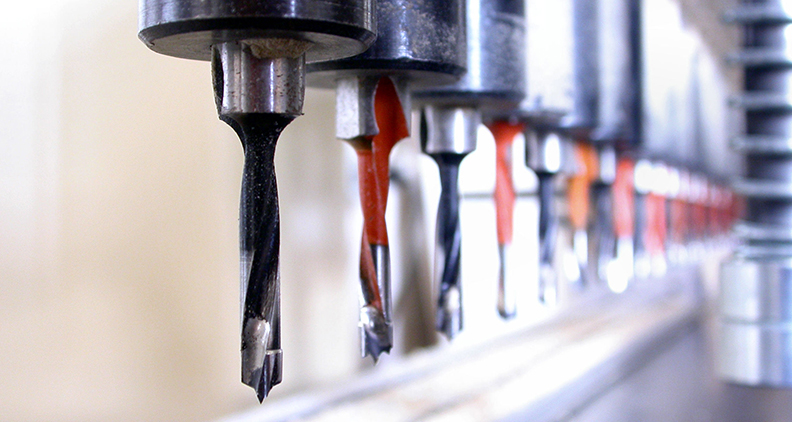

Feature size is one important consideration, as surgeon and patient demand for less invasive procedures increases, says James Eastwood, Engineering Manager of Implants at Precision Medical Technologies.

“As surgeries become less invasive, features become smaller,” he says. “At some point, they become so small that they’re difficult to manufacture, they require smaller tooling, and you have to cut it a little slower. It increases cycle times by decreasing the size.”

Tolerance is another important design element to consider, as tolerance negotiations can slow the manufacturing process.

“Often times, we’ll see very tight dimensions that are not needed on a print,” Thornburgh says. “If you put James Eastwood in front of one of our spinal implant designs early in the process, and that designer would tell him where he needed the tight tolerances on that part, Eastwood would be asking him, ‘Do you really need this radius to be this tight or this slot dimension to be this tight?’ ’’

Dan Owens, Vice President of Global Advanced Manufacturing at Paragon Medical, also notes the challenges that manufacturers experience with tolerancing.

“The computer age has ushered us into an unforgiving world in the manufacturing environment,” he says. “Even though machines can hold tight tolerances, there are still factors that come into play, the two biggest variables being the operators and tool wear. That’s a constant battle with tolerances.”

Not accounting for tolerancing can drive your scrap rate up and your quality down because the product is subject to revisions between you and the manufacturer, though tight tolerances may be required in some cases, Owens says.

“These features [that require tight tolerances] require precision machines and precision machinists to repeatedly produce in a production environment,” he says. “What is important is that the design has been critically examined to ensure that 1) it is truly needed, and 2) that every dimension is not CTQ (critical to quality). When you cannot prove capability on a feature, it drives 100 percent inspection, and 100 percent inspection is only 80 percent effective, then take into consideration gauge R&R correlation and it will effectively drive escapes, which means returns from the customer.”

Owens uses a pictorial to explain to customers the size of a micron to depict tolerances.

“The picture illustrated is that of a human hair. Inside the human hair is a piece of pollen that is 30 to 50 microns,” he says. “There’s a ragweed that is 17 to 23 microns and a dust mite that is ten microns. The human hair is 50 to 70 microns in diameter. One micron is illustrated inside of the hair, the hair being a four inch diameter blown up. The other microns are depicted in a little white sphere inside that. The point with this picture is this, do you really understand the correlation between what is required and what is computer default, as it relates to tolerances?”

Creating a repeatable process to account for tolerancing in a design goes a long way, says Ken Gredick, Engineering Manager at Triangle.

“A lot of times, designers will put something down and they’re not 100 percent sure that their tolerancing is correct, whether it’s geometric dimension and tolerancing (GD&T), or just a straight tolerancing,” he says. “If they called it out just a different way, it would pass all the time, but the way they had it detailed on the print, it could fail at 50 percent of the time. This makes a big difference when it comes to compliance.”

It’s also beneficial to have some understanding of inspection techniques, Gredick says.

“Inspection, in terms of standardizing inspection techniques, is an overlooked area that needs to be investigated and approved by the quality engineers on both ends,” he says. “Streamline radiuses for your off-the-shelf radiuses or inserts that you could buy, like McMaster Carr, just to standardize processes so you don’t have to go out and customize processes. All of those processes really add up to time, and that’s where we get killed, is on the time.”

Medtronic employs their DRM program (Design for Reliability and Manufacturing), which trains engineers and personnel in the R&D, product development and design quality departments. Through the program, engineers create prototypes to confirm whether a design can be manufactured in a capable process that adheres to budgets and timelines.

“We created a product development center, and once we have a draft, we try to make it here first,” says German Candia, Manager for Design Quality Engineering at Medtronic. “We try to catch issues around tolerancing and manufacturability early instead of later, before we transfer that to the supplier. That’s a new initiative this year.”

The tools within the DRM program allow engineers to account for feature size and inspection by performing MSA (measurement system analysis) and SPC (statistical process control) from the supplier to ensure that they are capable of performing the manufacturing processes.

“We don’t know how hard the design is to measure until we perform MSA, also known as a gauge R&R, typically,” Candia says. “Once we are able to measure [the features in the design], we will proceed to see how capable the process is in manufacturing.”

Input on the manufacturing considerations mentioned above can come from a variety of places, whether internally from colleagues within your organization, or externally from your manufacturing partners.

Ask your manufacturing partners the right questions before the design is frozen, like what manufacturing processes they employ, and how they manufacture similar products.

“It’d be very good to know what their typical process flow is for a similar product, because if you can leverage what they have, that’s typically your best way to drive cost down,” says Ken Trimmer, Senior Director – Chief Engineer, Knee at Stryker Orthopaedics.

Candia also emphasizes the importance of ensuring early on that your supplier is capable of meeting your manufacturing requirements.

“One challenge with the supplier is, yes they may be qualified, because they have a quality system, but the capability is not always there,” he says. “There is a lot to do before they even get the manufacturing transfer; they need to qualify the processes or the machine process for us. Suppliers are sometimes behind our requirements. When you start working with a supplier and realize that they may not be able to meet these requirements for MSA or capability, or sometimes quality, that’s when things get hard.”

Ultimately, you have to know what you want your product to do, Trimmer says.

“That sounds obvious, but I think a lot of engineers start designing before they’re even 100 percent sure what [the product] should do,” he says. “As OEMs, we can make sure we’re clear on the objective of the product. What does it have to do? What has to change or be different? What doesn’t have to be different? We have to know what’s really important to the device and maybe what’s not that important, because I think that’s your starting round for discussion with your manufacturing colleagues. If you’re looking at a design or an instrument and they say, ‘I already have something that will do what you need,’ or, ‘I can give you 80 percent of what you need off the shelf,’ that’s probably a good way to start.”

You also have to involve the right people on your team, including early buy-in from your supplier management group, operations, product development and marketing.

Owens agrees with this, iterating the importance of involving management within your organization.

“Sometimes the quality and the design teams operate in a vacuum; that message isn’t sent up the chain of command far enough to someone who is also looking at this as a business,” he says.

To achieve these synergies, it’s crucial to be flexible and not get so locked into the design that changes are too difficult.

“If surgeons give you good feedback on a design, it’s hard to change what you’re doing,” Trimmer says. “So if they like a prototype that you’ve shown them, and you bring in your manufacturing colleagues later and they say, ‘It’s going to be kind of hard to make, what if we changed it and went this way?’ Now you have to go back and show the surgeon again and say, ‘Well, I know you liked the other one, but what do you think of this one?’ The challenge is getting that discipline to bring your partners in early and make sure you’re setting expectations with your customers during the design process to say, ‘This is a concept and it may very well change before we finalize it.’ ”

Just as the solid relationship and open communication with your manufacturing partner is key, the same holds true with surgeon customers.

“Typically in this industry, you put a piece of metal that works in someone’s hands and their natural inclination is to think that it’s done,” Trimmer says. “It’s just constant communication and reminders of, ‘We’re trying these, we want to refine this, and the next one you see might look different.’ One way to handle it could be to hand them multiple options, and say, ‘Here are two to three different ways I can do this. What do you think?’ ”

Candia agrees. “If you really want to have a successful product launch, you need to listen and work with your customer from the very beginning,” he says. “We need to make sure we are collecting the right information on what they need and translating that into the design. When we translate that into the design, we translate that into the manufacturing, and with good manufacturing practices, from there you will have a successful product launch.

Send comments on this article to Carolyn LaWell.