Unique Device Identification (UDI) and sterilization should be driving influences for orthopaedic device packaging in 2016 and beyond. With increased regulatory guidelines in the form of FDA’s UDI guidance on convenience kits, along with tightening price pressures, the way device packaging is done will change.

“We’ve seen a considerable push to move from hospital-sterilized product to single-use terminally sterilized devices, taking things that normally would be autoclaved at a hospital and instead providing that device directly to the hospital, already packaged and sterilized,” says Brian Nissen, Principal Project Engineer at Quality Tech Services.

Additionally, getting a product to market is a long process, says Stu Krupnick, Director of Marketing at UFP Technologies. “Anything that we can do as a supplier to speed up the process is of value,” he says, and as more implants move toward sterile packaging, “That requires that the packaging maintain the sterile barrier, which can be challenging, because some of these items are sharp or abrasive.”

The Impact of UDI

Developments in UDI regulations are driving change in the packaging market.

In January 2016, FDA released a draft guidance document titled UDI: Convenience Kits. The document was meant to clarify the definition of convenience kit, reducing the number of accepted exemptions and requiring more individual devices to be marked with UDIs. Specifically, it noted that a non-sterile orthopaedic device tray or set would not be a convenience kit. FDA states that, because the implants and devices contained within are not meant to remain packaged together, that kit cannot qualify for the exemption.

This document followed the July 2015 draft guidance that indicated that direct marking on the device itself is required if the device is intended to be used more than once and intended to be reprocessed before each use, in order to ensure identification of the devices through their distribution and use.

Nissen’s colleague, Gerry Gunderson, Vice President, Quality Tech Services, says that pending UDI labeling regulations are part of the reason for the push toward terminal sterilization. “I think industry had hoped that, for a hospital sterilized procedure kit, a single UDI would be sufficient. Recent guidance has squashed that,” he says.

Tom Williams, Senior Vice President of Marketing and Strategy at Millstone Medical Outsourcing, says that new obstacles have surfaced for packaging companies. “The latest guidance surrounding what constitutes a ‘convenience kit’ may provide some challenges to the current delivery model of implants and instruments being provided in a non-sterile kit, especially within the spine and trauma markets,” he says.

Gunderson agrees. “That small requirement, that medical devices bear a UDI and a human readable, set off a whole chain of events in terms of label layout and label size selection,” he says. “Suddenly, you have a need in label validation and production to have a tool that could interpret machine readable codes.”

Williams believes it may be “extremely difficult” to direct mark certain items. One possible solution, he says, could be to sterile package items individually, allowing for UDI compliance. In fact, UDI guidance “may create a larger demand for sterile packaging, especially in spine and trauma verticals that have historically provided the majority of product in a non-sterile state,” Williams says.

“We have customers that are moving in that direction,” Gunderson says. “They’re getting away from the bulk pack and letting the hospital worry about the kitting and sterilization, and driving it back to individual pouched or packaged, individually labelled and uniquely sterilized.”

Gunderson adds that this trend puts the risk of the sterile claim away from the hospital and back onto the people doing the packaging.

Sterile Catalyst

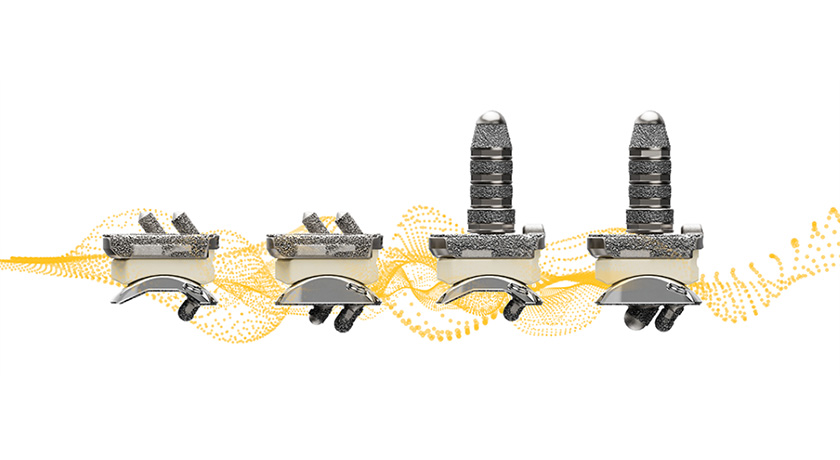

Over the last 12 to 24 months, UFP Technologies has also been asked to produce more sterile packaging components for devices, particularly those related to spine, Krupnick says.

“More and more implants are moving to sterile packaging, specifically spine and trauma devices, plates, screws, rods,” he says. “As opposed to the hospital sterilizing on-site, many of these implants are moving into sterile packaging.”

As more companies seek sterile packaging, Krupnick says, there is a shift away from polyvinyl chloride (PVC) as a protective material.

“The reason for that is the leeching of a plasticizer called DEHP, which is used to soften PVC,” he says. “Most European manufacturers have eliminated PVC entirely. Only a handful of U.S. companies have taken those steps. We anticipate that continuing, because DEHP can be a harmful material when in contact with humans.”

Increased infection rates at hospitals, European sales and regulatory implications on cleaning have also driven the sterilization trend, Williams says. “We have also noted an increase in sterile packaging of disposable, single-use instruments, as well as pre-validated packaging solutions.”

Williams adds that the industry is still contending with the transition to Tyvek material.

QTS is also looking for durable, but cheaper, materials. “We’re seeing a change in customers pushing for less-expensive packaging,” Nissen says. “For example, things that are more recyclable or a shift from thermoform trays to a pouch with a mounting card. Mounting cards are fairly inexpensive and easily recyclable.”

Nissen adds that while pouches are Tyvek-based, his company has sought to innovate with supplementary materials included in the pouches. “We’ve been looking to add more substantial pouch materials to our pre-validated product line, at materials that are more puncture resistant, pouch materials that offer barriers for oxygen or moisture, protection for light-sensitive products,” he says.

In addition to shifting material needs, Nissen suggests considering the end-user of your package: nursing staff.

“If you’re actively questioning the need for single versus double barrier, gathering the proper design input is crucial,” he says. “You need to spend time with your OR people. Those are your customers and they will tell you what works for them.”

Nissen stresses that for package designers, the benefits of spending time with perioperative nurses and scrub nurses can be immense. “We’ve found that even a few hours with a scrub or surgical nurse is worth several months of engineering experience,” he says.

This article was updated on March 23, 2016.

Julie Vetalice is ORTHOWORLD’s Editorial Assistant. She can be reached by email.